Audio Blog: Infield Basics

Most people don’t understand how much work goes into maintaining baseball and softball infields. In this comprehensive blog post, we’ll discuss four factors for sports field managers to consider. We’ll look at native versus engineered soil; components of an infield mix; silt-to-clay ratio; and conditioner depth.

Native or Engineered Infield Soil

Selecting the right skinned infield surface is vital to the safety and playability of a baseball or softball field, and your choices will come down to engineered infield soil or native soil. Which is better? You be the judge.

Native Soil

Native soils are usually harvested from creek beds locally and mixed with sand via a wheel loader. This type of mixing is very inconsistent, making every load slightly different from the last and testing critical.

Locally-sourced, native soils are composed of sand, silt, and clay. However, they tend to be high in silt. Silt becomes soft after a rain event and quickly reaches its saturation point. As a result, it usually takes a long time to dry out and can cause a delay or even the cancellation of play.

When native soils are dry, they tend to be extremely dusty and hard. The dust plays a factor on dry, windy days when it causes debris to get into players’ eyes. In some instances, play becomes paused until the wind gusts die down.

Engineered Infield Soil

Like native soils, engineered infield soils are also a mix of sand, silt, and clay. However, the components are balanced based on the soil makeup determined for the location and level of play. Recreation fields have a low percentage of clay, while college and professional fields have a higher percentage.

Rather than being harvested from the ground locally and mixed, the components of engineered infield soil are blended using a computer. The computer controls the sand, silt, and clay percentages and loads the materials into separate hoppers. It then releases the proper percentage of each component and sends them down a conveyor belt to make the mix the same on every load. These mixes are more stable, reducing the dust factor and controlling the silt.

Other Engineered Infield Soil Considerations

- The structure of engineered infield soil remains stable when wet, so slipping and sinking are minimized.

- Because the structure remains stable, the engineered soil mixes are much more firm after a rain event and become playable quickly.

- Engineered infield soil will not migrate or become dusty in the summer.

Components of an Infield Mix

The infield mix is the soil used to build the skin surface of a baseball or softball field. Infield mixes are made up of three components: sand, silt, and clay.

Sand is considered the largest soil particle in the infield mix. It helps create a strong infield by supplying structural integrity. When dry, sand does not crack, and it is excellent for drainage. The infield mix is in the acceptable range when it’s 58-75% sand. Shoot for retaining over 50% of the sand on the medium sieve.

The second-largest soil particle in the infield mix is silt. Silt links the sand and clay in an infield mix by filling in the particle size gap between them. Silt, along with clay, handles wear well when correctly managed, which makes it perfect for high-traffic areas. 10-35% of silt in the infield mix is considered in the acceptable range.

The smallest soil particle, clay, supplies strength, and color to the infield mix. A hydrated infield would be hard to achieve without clay. Clay helps retain moisture, so dryness does not cause damage to the skin. 15-35% is the acceptable range of clay to have in an infield mix. The ratio of silt/clay (SCR) should NEVER be higher than 1:1.

What should we look for in a good mix? Traction, playability, and consistency. A good infield mix will have consistent traction, known as the ability for athletes to play without sliding and slipping. The infield should also play consistently in various weather conditions, which a good mix will provide. A good mix has many characteristics, but those are the most important.

What Is a Silt-to-Clay Ratio?

The silt-to-clay ratio or SCR came about to help groundskeepers decide if their infield mix had the correct amount of clay and silt. So how do you figure your SCR? Divide the silt percentage into the clay percentage.

A mix contains 75% sand, 20% silt, and 5% clay: 20 / 5 = 4 SCR

An SCR of 0.5–1.0 is the best infield mix at any level of play. Note: While an SCR between .5 and 1.0 is the best at any level of play, the amount of sand and sand size (retain over 50% of the sand on the medium sieve) in an infield mix needs to be adjusted for different maintenance levels.

What happens if your SCR is less than 0.5? If it’s above 1.0? Here’s a look at the three types of SCRs.

Low SCR (0.1–0.5)

Low SCR infields tend to separate during play. In this situation, silt, the link that holds the sand and clay together, is low. Since there is insufficient silt in the infield mix to bind it together, a low SCR infield will break apart and create lips as the high sand content migrates to the edges. You are also likely to find chunks of infield mix on the infield during play when an infield has a low SCR.

Balanced SCR (0.5–1.0)

An infield is balanced when its SCR has slightly less silt than clay (equal part clay and silt). A balanced SCR infield allows for cleat-in, cleat-out play and has a corkboard-type feel.

What are a few characteristics of a balance infield? First, the infield will dry fast and not migrate to the edges. It will also not be slippery when it’s wet, and it will not be too hard when it’s dry.

Elevated SCR (1.0+)

There is good news if your infield’s SCR is slightly above elevated (1.0-2.0). If appropriately managed, infields with slightly elevated SCRs will most times play well.

What is a clue your infield has an SCR slightly above 1.0? The infield’s material will push out of both sides of your shoes when you step on the infield wet.

When infields have SCRs above 2.0, the infield may play well for a short time. However, the problems will inevitably begin. SCRs at 2.0 have two times the amount of silt to clay in the material, which results in infields with this SCR having a dust layer on the skin surface and a hardpan underneath. An infield with a high SCR will erode in high wind conditions, and the material will migrate to the edges. Low areas may also develop around bases. Usually, high SCR infields have a blond/light tan appearance.

Infield Conditioner Depth

Infield conditioner is a crucial part of any field maintenance program. But not all fields require the same amount of conditioner. How do you know what depth of conditioner is right for your field? It depends on several factors, including the level of play and the base soil composition.

The silt-to-clay ratio (SCR) of the base soil affects how much conditioner the infield needs. The higher the SCR, the more conditioner is needed. An infield mix with more fine or very-fine sand also requires more conditioner.

If the infield has problems maintaining moisture and becomes overly firm during dry seasons, that’s a sign it could use more conditioner. Recreational fields tend to need more conditioner than higher-level, more maintained fields.

Ultimately, you want to manage the top quarter-inch of the infield to provide consistent cleat-in/cleat-out play. The examples below are some helpful case studies in determining infield conditioner depth.

|

|

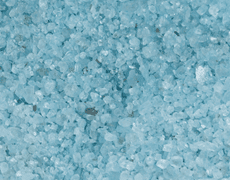

The photo above is an infield mix with a high SCR of 2.5. This field hosts high school and recreational play. It would need more conditioner, at a depth of about 1/4 inch.

|

|

The photo above is an infield with an engineered soil that has a balanced SCR of 1.0. The field hosts professional play. It would need less conditioner, at a depth of about 1/8 inch.

Your ATS sales representative is the best resource for questions specific to your field. Contact your rep today to talk more about any of the factors discussed in this blog post.

<div id=”buzzsprout-player-