Why You Should Buy Foliar-Pak XCD Coated Seed

The debate on whether to use coated or uncoated seed has a long history, with many on both sides. At Advanced Turf Solutions, we favor coated seed, especially seed with Foliar-Pak’s XCD coating, and here’s why.

A Little About Foliar-Pak’s XCD Coating

XCD is made up of three primary components: water-absorbent technology, fungicide, and supportive nutrients that help increase germination and enhance soil surroundings. XCD’s water absorbent technology holds 600–1,000% of the seed’s weight in water, allowing for a longer between waterings, helping to conserve resources.

The fungicide component of XCD is Apron XL® fungicide (mefenoxam). It decreases damping off and pythium while increasing seedling survival.

The supportive nutrients portion of XCD is a mixture of minerals, amino acids, biology, and Armament® technology. The amino acids and Armament work in synergy to enhance soil surroundings and increase nutrient uptake through roots.

Benefits of Using XCD

Increased Chance of Seed Survival. No one wants to open another seed bag after the first seeding did not go as planned. Using seed coated with XCD will help stop the chances of having to seed again and increase the chances that the seed will establish and develop into a mature plant. Seed coated with XCD improves the survival of seedlings for two reasons.

The first reason: XCD coating does not disappear as the seed grows; it sticks more readily to the soil, keeping the seed in place. By staying put in the soil, the roots can keep wet and use the moisture from the coating to germinate, obtain healthy roots, and grow into a mature plant. Those things allow for a better chance of achieving full coverage and thick turfgrass, making for good-looking lawns and excellent play on golf courses and sports fields.

A seed coating that can hold moisture also allows the seed to survive in hot and dry conditions. Typically, seeding is not done in July or early August because the plants will die once they come up. But with XCD coating, the seed’s stress tolerance improves, and a longer seeding window opens.

The second reason: Apron XL® (mefenoxam), the fungicide in XCD coating, protects the seedlings against diseases, especially in hot conditions, and ensures the seedling has the nutrients needed to begin development. The addition of mefenoxam also decreases the need for additional fungicides.

Water/Irrigate Less. We are all looking to save time, and coated seed can help. XCD coating holds in moisture, so the plant does not need to be watered as frequently. The coating is excellent for a situation where you can’t depend on irrigation.

For example, in a lawn care setting, say you are overseeding, but your customer, for whatever reason, does not have the ability to water. So, you’re throwing seed out there and hoping it gets enough irrigation. With XCD coating on the seed, any irrigation you get, any rain you get, will be sucked up by that coating held against that seed and make it germinate better.

Here are two other examples, this time, for irrigation situations at golf courses. XCD gives more latitude and flexibility with irrigation timing because the coating holds moisture, especially during irrigation malfunctions. The coating also helps in divot recovery. The Sand and Seed mixture used in most divot-filling operations can quickly dry out between irrigation cycles. The moisture held close to coated seed increases seed survival and the chances the turfgrass will grow and fill in those divot voids.

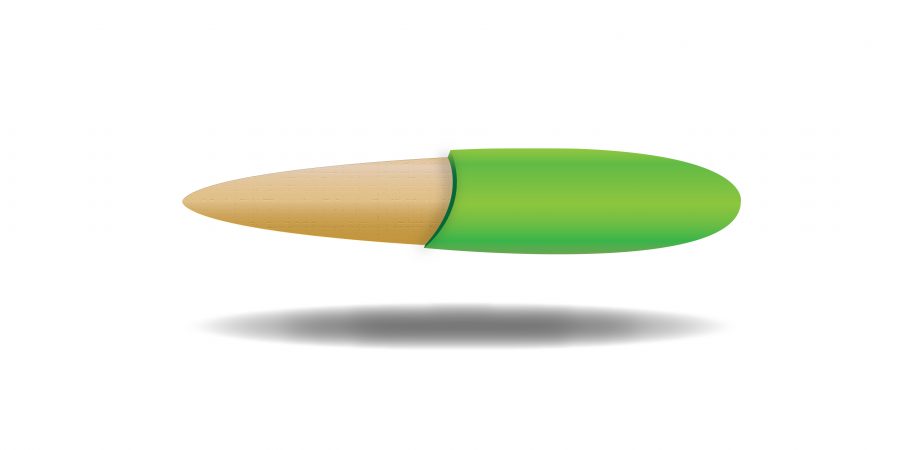

Uniformity While Seeding. Whether using a slit seeder or rotary spreader, you can fight inadequate coverage with XCD-coated seed. If you’re seeding with a slit seeder, uncoated seed may blend into the trench you’ve created and make uniform coverage difficult. XCD-coated seed, with its bright-colored coating, will be highly visible, making uniform coverage easier to reach.

XCD coating increases the density of seed, which in turn, increases the ballistics, especially if you’re using a rotary spreader. Better seed ballistics negates the effects of wind, giving you more uniform coverage.

More uniform coverage is also possible when employees make repairs by hand. The bright green color of XCD allows them to measure how much seed is used visually.

Customer Visibility. Sometimes our customers need to see we are working. Coated seed can help assist with this. Customers will know you have done work, like filling in thin areas of turf, because they will see the bright color of the coated seed on the ground.