The Value of a Properly Graded Infield

Many things make up a safe, playable infield skin on a baseball or softball field. No matter the age group, skill level, or budget situation of your facility, a properly graded infield will provide significant value regarding safety, playability, and protecting your material investment.

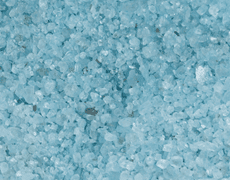

A common misconception around baseball and softball fields is that the game is played on grass and “dirt.” Though that isn’t false, it isn’t entirely true, either. Infield mix and engineered soil are better ways to describe the skin portion of an infield rather than “dirt.” Sand, silt, and clay make up an infield mix, and there are many options for these throughout the country. Typically, these mixes are 60–75% sand and 25–40% silt and clay. We recently launched a new line of infield products, including an infield mix with an SCR of 0.5–1.0.

Once you’ve decided on an infield mix that’s best for you, having it installed during new construction or amended into your current mix requires laser grading. Laser grading uses laser technology to grade an infield to the desired slope. Too steep of a slope will result in loss of field material to areas you don’t want it, and too flat of a slope will mean the field doesn’t shed the water as designed. Simply adding material to a low area and using the naked eye is not going to solve the problem. It will most likely move the standing water to another area or create a high area that needs to be leveled out.

A good comparison to a properly graded infield is a properly graded stretch of road. There’s still water on the road after a rain, but the water will eventually shed off the road toward the designed drainage system. An infield is no different. Once the material is placed on the field and graded, a roller should compact it down to create a smooth, safe, and playable surface that will shed most of the water that falls on it.

After the field has been rolled, adding a quarter inch to half inch of calcined clay or expanded shale conditioner is recommended to help manage moisture on the field as well. Our new line includes three calcined clay conditioners with difference mesh sizes and uses.

Like a stretch of road, an infield skin will eventually need repair as freezing, thawing, maintenance practices, and significant use will create imperfections on the surface. Laser grading your infield annually, preferably in the fall when play is complete, is the best practice. This ensures any high spots have material moved to low areas, maintaining a safe and smooth surface. Adding a load of material every other year and having that graded is another good option.

Protecting the players from injury and protecting the investment of field material are two key values of a properly graded infield. Being able to play on the field as fast as possible to reduce a delay after a rain event is another. All three require some planning to create a properly graded surface.

Brian French

Sales Representative